Depending on the anaerobic digestion system chosen, the desired total solids content of AD influent ranges from between 6 and 12%. Assuming equal hydraulic retention times, lower values of influent TS result in larger tanks and higher operating expenses due to the need to heat water, which has no fuel value. Last month in part 1 of the discussion on manure dilution and anaerobic digestion, we discussed sources of dilution, estimated quantities, and the effects of dilution on AD influent total solids (TS) content. To review, it was shown how manure excreted at 12% TS could reasonably be diluted to 6% TS, assuming some typical volumes for dilution water added as part of the milking process.

In this installment, we will explore the concept of manure thickening, which is the process of pre-treating manure to potentially affect AD influent. Even with thickening, keep in mind a liquid fraction is produced in addition to the thickened fraction, and to qualify for low-carbon fuel standard (LCFS) credits, 100% of the manure stream—including the liquids—must be digested.

Thickening

Thickening is the term used to describe the process by which dilute manure is dewatered using liquid-solid separation systems. Dewatering is usually achieved using sloped screens or internally fed rotary drums.

Figure 1: Rotary drum (L) and sloped screen (R) separators for dewatering and thickening manure.

TS of the captured solids is dependent upon influent TS, screen size, water quality, and screen/plate cleanliness. Figure 2 shows manure being thickened in rotary drum separators with mesh screen and perforated plate.

Figure 2: Thickened solids in rotary drum separators with mesh screen (L) and perforated plate.

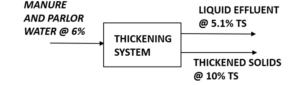

Solids separation in thickening systems is not to the extent you would see with bedding production (30% TS) where manure is squeezed after gravity dewatering to express a portion of the absorbed water from the solids. Dewatering with AD is simply the gravity draining of free water within (or on) a separator. If the input of a dewatering unit is dilute manure, the effluents are: 1) thickened fraction with TS greater than that of the influent and 2) liquid effluent with TS less than that of the influent. A sample material balance based on TS is shown in Figure 3.

Figure 3: TS-based material balance for thickening system

Depending on the influent TS and screen size in the solids separator, the TS of the thickened fraction can range from 6 to 12%. Most designers and developers would agree that this is quite appealing for AD influent. But wait. What about the liquids? In the Figure 3 example, along with solids at 10% TS, liquids are produced at 5.1% TS.

The Myth

Thickening as intended by many designers and developers is a myth. Remember, the purported goal of manure thickening is to take a dilute manure stream and make it more amenable to AD by increasing the TS. The challenge is solids separators used in dewatering systems are not anti-matter machines. Whereas they do produce a thickened fraction that is much more amenable to AD, they also produce a liquid fraction and this liquid fraction must be digested as well. So, if the composite TS of manure influent (not including process water for alley flushing or flush fluming) is 4% TS, the digester influent will be 4% TS.

The best way to ensure a thickened manure feed going to AD is to minimize water inputs on the dairy to the extent possible, keeping in mind, of course, milk is food and cows are mothers. A certain amount of fresh water is required to produce high quality milk and maintain cow health and comfort.

In essence, manure thickening systems do not destroy matter. What goes in, goes out and what goes out must be digested or bypassed around the AD and bypassing water around an AD is generally not an option.

Reality

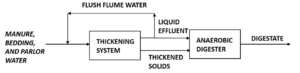

Assuming 100% of the manure and water on a dairy will be digested, the TS of the AD influent can never be greater than the composite TS of the manure and water effluent produced by the dairy. Thickening does have merit where manure is being diluted in the conveyance process whether by flush or flush flume. For instance, if manure flush flume effluent is 5% TS and the composite manure influent going into the flume is 7% TS, it is possible to thicken manure, but only back to the “original” 7% TS. The excess liquids in effect are used again in the manure conveyance process. Figure 4 is manure thickening with water being recycled in a flush flume with excess liquids discharging to the digester along with thickened solids.

Figure 4: Manure thickening as part of a flush flume system with AD.

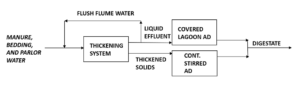

In certain cases where a high volume of fresh water is used, even thickening back to the original TS results in excessively large AD tanks. As shown in Figure 5, thickening can be used effectively to produce a high TS product to be digested in a continuously stirred tank reactor (CSTR) and a low TS product that is digested in a covered lagoon. This way, the size of the CSTRs can be minimized, recognizing they are more expensive to construct on a per-gallon basis and operate.

Figure 5: Manure thickening as part of a flush flume system with separate AD for thickened solids and liquids.

Maybe

Thickening, although often considered as part of an AD system with dilute influent, is almost equally as often misunderstood to be something of an anti-matter machine or process.

Can manure be thickened prior to AD? Yes. But without bypassing manure around a digester, can manure be thickened to a TS greater than the composite manure (and parlor water, deck sanitation, spilled waterers, etc.) TS entering the system? No. Thickening systems do not make water disappear.

When manure composite TS is less than what is desired for the chosen AD technology (e.g CSTR), consider thickening, and not bypassing liquids, rather, consider perhaps a lower cost, covered lagoon digester for the liquid fraction.

Thickening is a tool, and like any tool, it should be properly used and used in the right places. Consult with a qualified vendor or design professional to select and design the best thickening system to address a dairy’s manure inputs and manure management routine as well as the requirements of a proposed AD system.

If you have questions or would like more information on how Settje could assist with your dairy manure digestion, contact your local Settje consultant. If you don’t have a Settje consultant, you can contact us directly.